JTEKT Torsen North America will be closed for the week of December 26th, returning on the 3rd of January. Also, much of the staff will be off for at least part of the week prior to the Christmas holiday. As such, any orders placed through the website after December 21 will not be processed until we return. Emails may not be replied to until after the new year as well. We wish everyone a happy holiday season, and look forward to working with you in the new year. Cheers!

All posts by Rick

Happy Holidays from JTEKT Torsen!

A Torsen New Year

With 2016 officially on the books, we all like to take a moment to reflect back on what that year brought us. Here at Torsen Intergalactic, a lot of things took place that were noteworthy. Most obvious to all of you was that a brand new website was launched, replacing that clunky old frame-based site that looked it was created around 2000 (because it was). This has given us better ability to hawk our product, tell you why its awesome, communicate to readers (by way of this news page), and of course, has improved your ability to connect with us. But 2016 also brought us a number of things that you wouldn’t see from your side of the internet.

In 2016, we ramped up to volume production for the Ford Mustang GT350, as well as relaunched the front differential for the F-150 Raptor (now a $500 stand-alone option on Ford’s website). These, combined with the ongoing Mustang GT differential production have served to significantly increase our OEM sales volume. That led us to hiring more staff and adding more equipment. We added a new gear cutter and a new gear inspection machine. We’ve contracted to have a new assembly line as well. Inside the Torsen Cosmic Headquarters building, we’ve knocked down several walls, rearranged the machine shop and rejiggered the assembly area to accommodate the new machines in a sensible way.

On another front, we had an excellent turn out and response to our booth at the SEMA show in Las Vegas. We attended the PRI show for the first time in a long time. We’ve added several new models to our aftermarket line, and we’ve identified segments of the market that we feel are ripe for new offerings. Look for additional new models in 2017.

That’s not to say its been all rainbows and unicorns. There have been issues along the way – some rather significant. However, it wouldn’t be proper to discuss these in polite company. Needless to say, said issues have been resolved and the world is now as right as it should be. So where does that all leave us going forward? Well, we expect 2017 to build on what we’ve achieved in 2017 and ring in new areas of growth.

For starters, the new assembly line is being installed as we speak, or, at least as I type this. Another new gear cutting machine is on the horizon, scheduled to land in late spring. This piece of equipment will have several unique features that will allow us to make gearing components unlike any made by those other helical gear makers, and will allow us to fully produce whatever we need in-house. That will truly open up our prototype and low-volume manufacturing flexibility.

Also, as mentioned above, we’re planning several new aftermarket models to help round our our product list. We intend to offer product for segments that are sorely lacking in our current line, while also expanding our motorsport offerings – particularly in off-road racing, as well autocross, track use, etc. At this time, I think its fair to say that we’ll be back at SEMA in November, but right now that seems a long time away. Either way, we’re also working to be more responsive to customers, both in terms of listening to what you want, but also in addressing general day to day communications.

All told, 2017 looks potentially quite bright, with projected volume increases, sales expansion and newfound manufacturing capacity that’s coming. We look forward to working with you in the new year!

New products available!

Wow, this year is going by fast. Here we are in the middle of February already – and posts on the news page have been a little lax. Well, good news: several new products have been added to the Torsen webstore.

Has the thrust block for the Torsen diff in your Boss 302 gone on vacation without you? Perhaps your pooch buried it in the backyard, or maybe your buddy decided to play a practical joke on you. Either way, you can’t finish installing your Torsen into a Ford 8.8″ axle unless you have the center block. The block, also called a thrust plate, not only spaces your axle shafts apart, it also supports the thrust load of the differential’s side gears during operation, and as such is essential.

Many times, these blocks get lost during the time between removal and reinstallation. Well, Torsen can help. Replacement thrust blocks are now available in our webstore, and include a replacement retaining bolt. This block kit fits the Torsen differential found in the 2012-14 model year Mustang GT, Boss 302 & GT500 models (Ford part number CR3W-4026-AB), the same model sold by Ford Racing (part number M-4204-MB), as well as all recent T-2R models sold for the 8.8” axle (Torsen part number 975420-0200AF).

We have also added a split thrust block kit that fits Torsen differentials for the GM 7.6” axle application. This kit is intended for use in OEM-production Torsen units found in 1999-2002 Camaro & Firebird models, with identifying numbers starting with 9021-, 9022-, 9023- & 9032- and will also fit late T-2R applications for the same axle (part number 975420-0315E). This two-piece block is split into two half-thickness blocks, allowing the installation of ring & pinion gear sets with ratios numerically higher than 3.42:1. So, it you want to install 4.10 gears, this is your ticket.

One additional new product – we now have available direct-replacement differentials for the late Ranger FX4 Level-2. These are complete assemblies, and only fit Ranger models with 31-spline axle shafts. They can also be used in older Explorer models with a solid rear axle, but are not compatible with IRS applications or Mustang axles.

How a Differential Works, a Video

How Much HP Can it Handle?

An extremely common question that we hear, here at the Torsen® Cosmic Information Center, is “how much power does this handle?” To which, I like to answer: how much do you got? While a little glib, it gets to the truth of the matter, which is that we don’t really care – from the differential’s perspective – how much horsepower you have. That’s not to say that I wouldn’t find it extremely cool to know you’re making 800HP with a roots-type blower on your Camaro or that you’ve put long-tube headers and Ford Racing cams on your Boss 302 (because that’s awesome if you have!). But what the differential – and the entire drivetrain – really cares about is torque, and frankly, your “at the wheels” torque numbers from your latest dyno pull is pretty meaningless as far as that is concerned. At the same time, most people look at me like I have a third eye when I tell them how much torque our differentials are actually rated for.

Let me explain. Horsepower is really a rating of how much work can be done over a period time. In practical automotive terms, unless you’re concerned with setting a record at Bonneville, it’s a bit nebulous – it’s really just bragging rights. Conversely, torque is a measure of the engine ability to actually generate rotational force – what turns the shafts, which turn the gears, which turn the wheels. You can argue that torque and horsepower are mathematically related, and you would not be wrong. However, torque is what actually accelerates and drives the vehicle, whereas horsepower is what pulls it to its top speed. So, torque is what actually loads the drivetrain, and what can actually “shock” the differential in a severe situation. Consequently, torque capacity is a primary design criterion for developing a differential rather than horsepower.

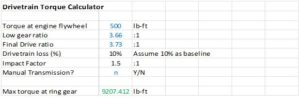

OK, so what does that mean to me, you ask? How much torque can it handle? Now you’re getting somewhere. It is important to understand that torque is multiplicative with gearing – the amount of torque delivered to the wheels during your dyno pull when in 4th gear is not the same amount that will be delivered in 1st (or any other) gear. And that’s what you have to keep in mind. The axle, and entire drivetrain, is sized so it can handle a worst-case scenario of torque loading. That, typically, occurs at vehicle launch in first gear where the torque multiplication is greatest. To get an understanding of where we need to be in terms of torque capacity, it’s necessary to do a little math. Now, this is an extremely simplified version and it doesn’t take into account several important things (such as actual tire traction available) but it makes an interesting exercise because it shows you what sort of level torque your axle really can see. If you’re used to dyno pulls that reports 500 lb-ft of torque at the wheels, this will really open your eyes.

So, you’ll need to know your gear ratios, and you’ll need to have an idea of what to use for an impact factor. This extra factor accounts for the instantaneous shock-load that the drivetrain can see when you rev up the engine and dump the clutch, or otherwise launch your car from a standing start in a very fast, abrupt, manner. Basically, the sudden application of torque winds up all of the play and back lash in the system, then smacks down real hard with the sudden change of driveline inertia, like a sort of whip effect. This kind of launch can put a shock load on the system that is substantially higher than if you simply rolled onto the throttle while moving. For a manual transmission, this impact factor can be 3:1 or more, depending on abruptness of clutch engagement. In fact, some vehicles have limited how quickly the clutch can engage just to help protect from this. For an automatic, the factor is a bit more forgiving, more in the 1.5-2:1 range, depending on the torque convertor.

TQmax = Maximum spike torque at ring gear

TQeng = Peak torque at engine flywheel

R1st = First gear ratio

Rfd = Final drive ratio

I = Impact factor

TQmax = TQeng * R1st * Rfd * I

Let’s assume a late model Mustang GT, with an MT-82 manual transmission and 3.73:1 axle gears. The numbers go as follows:

390 lb-ft * 3.657 x 3.73 * 3 = 15959.5 lb-ft.

Yes, that’s nearly sixteen thousand foot-pounds of torque. See what I mean? Now, one very large caveat to this comes in the form of traction. You will only ever develop as much torque as you have the ability to resist with tire traction – that’s really just fundamental physics. Once you’ve overwhelmed the tires, any additional potential torque goes up in smoke; it would be lost to wheel spin if you stay on the throttle. We know from experience that the S197 Mustang example in question can really only use around 9500 lb-ft in stock form before becoming traction limited, so that 16K lb-ft number we calculated is very theoretical. But someone could begin to approach that by making suspension and tire upgrades. We also didn’t account for any losses due to drag in the drivetrain system (as I said, this massively simplified). But, this does point out the order of magnitude that your axle has to put up with. A mere 500 lb-ft is nothing.

So, back to the original revised question: how much torque can it handle? That varies depending on the application. OEM applications are typically designed to a specification set by the vehicle manufacturer. However, due to the wide range of possible places that an aftermarket differential can find itself in, and equally wide range of uses, the best I can tell you is that each application is engineered to have the most torque capacity is as practical for that axle model. That’s vague, I know, but the actual answer would require a matrix table to sort out. The answer is also somewhat meaningless unless the person asking the question has a way to evaluate the traction limitations of their car, and that is a whole separate discussion…

More about TBR, Lube, Friction Modifier & You

Torque Bias Ratio (TBR) – also referred to as Locking Effect – is a term used to quantify how much resistance to wheel spin a differential has. This is true of any type of LSD, plate or a helical design like Torsen®. These devices work by creating internal friction; friction in the diff is what allows it resist wheel spin.

By the same token, that resistance is also what allows a differential of the non-open variety to distribute more torque to the side that can best use it. The higher the TBR setting is, the greater the resistance will be to the start of slippage. That means more torque can be sent to whichever tire has better traction. In essence, by building resistance to spin, the differential can hold back the wheel with lower traction from spinning, allowing the higher traction wheel make use of more torque.

The actual amount of friction that the differential develops will be different depending on if the internal gears are static (not moving in relation to the diff case) or if differentiation is taking place. Think of trying to push a crate across a floor – you need more force to get it to move initially than you need to keep it moving. The coefficient of friction is higher when things are not moving compared when to when they’re sliding. The same is true for the gearing in the differential.

So, there is more resistance to wheelspin when the diff gearing is not moving inside the case, which is the case when driving in a straight line. But when you turn, and one wheel speeds up while the other slows down, the differential gears want to move. Once there is enough force is on the axle shafts to overcome the friction, the gearing will start to move. In doing that, the amount of friction generated is reduced. However, this is true for clutches as well as for helical gears.

Now, that transition from static to dynamic friction is often kind of abrupt; torque gets wound into the gearing until the friction is overcome, then it pops free and moves. But when it does that, the movement slows and the coefficient goes up, and so it stops moving. At least, until the friction is again overcome and it pops free – again. In that transition, sometimes you find that stick/slip/stick/slip behavior occurs a lot. This stick/slip characteristic is also what causes clutch plates to chatter in a tradition limited slip device.

Bringing this all back around to friction modifier – the actual function of modifier (the “modification” it makes to the friction) is that it brings the static coefficient of friction down to a similar level as the dynamic coefficient of friction. This helps smooth out the transition from static to dynamic friction, getting rid of the tendency for abrupt stick/slip. This, as a result, largely eliminates the chatter or squeak . However, it does this at a price – the price of lowering the coefficient of friction for the whole system.

So, if we return to the notion that the differential is a friction device, it then stands to reason that the friction the differential generates is directly influenced by the lubricity of the oil blend that is used in the system. If the oil’s friction properties are reduced, the amount of friction that the diff produces is proportionally reduced. That, in turn, has the same affect on TBR. Usually, it is a small but measurable amount, maybe up to a 10% loss of TBR.

This begs the question of whether or not friction modifier is actually necessary in a Torsen. Like I said earlier, the modifier is beneficial in smoothing out the operations of friction devices. However, because our friction properties are different than that of a clutch plate differential, you might not see the same symptoms of stick-slip behavior that those would. As noted, clutch plate differentials have a distinct tendency to chatter without friction modifier in the oil, and that chattering can become very objectionable. So, the modifier is essentially a requirement.

In a helical gear diff, however, the stick-slip tends to show up as an audible noise, described by some as a “rusty screw” noise, or as a squeak or moan. You tend to hear it in very low-speed turns, when the steering is at or near full-lock. So, you might hear it while maneuvering in a parking lot, or turning the car around in your driveway. This noise is, as I said, just a characteristic of the friction properties, and is normal. But, if you hear it a lot and it annoys you, adding a few ounces of friction modifier to the axle lubricant will almost always eliminate it. So, the bottom line is it’s up to you.

Ask Torsen: Differential Contribution to Axle Temp

This question comes by way of www.mustang6g.com forum user Brent Dalton. This came from a discussion regarding managing axle temperature on the S550 Mustang and preventing overheating of the axle during track use. For reference, 2016 and newer Mustang GT models with the Performance Pack (PP) option (which includes a Torsen® differential) have a temperature sensor on the rear axle cover to monitor axle temperature and warn the driver if temps become high.

Quote:

| Originally Posted by Brent Dalton

…So it’s only really on 3.73 torsen diffs… so it makes some of us wonder… is it overheating due to the torsen and the regular type diff’s don’t suffer the same? A few guys … are working on the answer. |

This is a worthwhile question, especially as more people take these cars on track day events. A couple of comments – all limited slip differentials (LSD) are friction devices. The higher the TBR/locking effect is, the more friction it generates. So, the Torsen® in this car – with a TBR of around 2.8:1 (versus 1.8:1 for base clutch plate LSD) – does create more friction than the base differential does. However, with all of that said, friction only creates heat when you force slippage of the friction surfaces under high (torque) load. I think that if you could actually watch wheel speeds during track events, you’d be surprised by how little differentiation occurs, at least under load. At that TBR level, the Torsen® isn’t allowing the wheels to change speed much, even if it continues to bias torque side to side as warranted by traction conditions. In general, in track use under high torque loads, the TBR level is sufficient to prevent most differentiation. If you have a plug-in device that’s interacting with the vehicle CAN by way of the OBD2 port, see if you can monitor the rear wheel speed sensors and see what actually goes on during a hot lap. You might find it interesting.

Anyway, the differentiation level is low, and even when it does, the differential rate (referred to as delta-N) is also quite low – on the order of 15-20 RPM difference from side to side. So the frictional heating component that the differential contributes to the axle oil is pretty low, in relation to the system as a whole. You get a lot more heat generated by the ring and pinion due to the hypoid mesh, which is running constantly, and at much higher speeds than the differential gears operate at. Past that, most of the heat probably comes from external sources – like the proximity of the exhaust, which passes quite close to the axle carrier on this car. Combine that with the fairly small volume of oil available to absorb heat, and you get the situation you’re in.

In my opinion, likely the biggest reason that Ford monitors axle temp on Performance Pack cars isn’t because the Torsen® creates more heat, but rather because they see a greater need to pay attention to axle temp on those cars, due to the perceived (track) usage. I expect that in their minds, the non-PP GT models are much less likely to be on the track, so they (Ford) doesn’t need to spend the extra couple of bucks to fit those cars with the sensor. It isn’t that the non-PP axle is likely to run cooler, but instead they are less likely to be in a situation where excessive heat is generated.

Memorial Day closure

Just a heads up – JTEKT Torsen North America, Inc. will closed in observance of Memorial Day on Monday, May 29. Orders and emails submitted over the weekend will not be processed until the following Tuesday. There will also not be anyone about the office to answer the phones. Have a great weekend!

Ask Torsen: Type-2 vs. T-2R

Today’s Ask Torsen question comes to us by email from James Stapleton. He asks:

(I) Have seen where you’ve stated that a T-2 might be better suited for open tracking than the T-2R. I do both open track and autocross currently on Michelin Pilot Super Sport tires, and maybe changing to a 200 treadwear type tire in the near future. Thoughts?

Well James, that’s a great question – and one we’ve been asked a lot over the years. However, it is highly dependent on a number of things: chassis set up, track conditions and degree of technicality, even driver preference, so there is no singular hard and fast answer. The basic essence of the answer, though, is that it’s a matter of what trade-off is best for the situation in question.

As a limited slip differential becomes more aggressive – with a greater degree of lockup (or torque bias ratio) – it has greater resistance to differentiation. This has two influences on the car in the context of what we’re talking about here. First, it affords better resistance to wheel spin, which of course means that the driver can apply more throttle and accelerate faster. Second, it has greater resistance to steer input, at least during turn-in and initial corner exit, because by resisting differentiation, it is also resisting the car’s need to rotate and change direction.

This initial understeer is somewhat mitigated, at corner exit, by resisting inside wheelspin. In so doing, more torque is allowed to go to the outside tire once the inside tire reaches its traction limit than would otherwise be the case. That, in turn, has the effect of generating an understeer-canceling yaw moment on the chassis, serving to actually drive out of the corner with greater authority. But you have to overcome initial understeer to get to that point. This effect is described in more detail elsewhere on this blog.

To boil that all down to the nuts and bolts of the matter, higher TBR can make the car “push” some in a corner, but allows a great deal of corner-exit traction. Lower TBR, on the other hand, can be more neutral-feeling, but potentially lack sufficient traction to prevent inside spin. So, as with any aspect of chassis set-up, it’s a trade-off. Cars with lower torque output (such as a Miata or BRZ) can be comfortable with a lower TBR because they favor nimble response and don’t have the torque to overwhelm the tires. Big-bore cars with big torque output may need the higher TBR of a T-2R model.

However, as noted above, venue plays into it as well. A track that is fast and flowing will probably favor the lower TBR of the standard Type-2. With less dynamic weight transfer in a corner, you don’t need to compromise handling balance based on corner-exit traction. The lower dynamic weight transfer means the inside tire doesn’t become unloaded and loose traction as readily. But a smaller, more technical course – especially in autocross – may force you into a more aggressive differential due to tight corners and high weight transfer. There is a much greater potential to lift an inside tire off the pavement. Frankly, the T-2R owes its existence to autocross. It was due to the complaints of wheelspin and Type-2 not being aggressive enough in that environment that we created the T-2R product line. But again, it comes down to what compromise makes most sense to you.

In your specific case, because you participate in both open track events and autocross, I would probably prefer using the T-2R. It is easier to make some chassis tweaks to compensate for a little extra initial understeer than it is to cope with insufficient traction at corner exit. At least, that would be the approach I would take. Best of luck!