An extremely common question that we hear, here at the Torsen® Cosmic Information Center, is “how much power does this handle?” To which, I like to answer: how much do you got? While a little glib, it gets to the truth of the matter, which is that we don’t really care – from the differential’s perspective – how much horsepower you have. That’s not to say that I wouldn’t find it extremely cool to know you’re making 800HP with a roots-type blower on your Camaro or that you’ve put long-tube headers and Ford Racing cams on your Boss 302 (because that’s awesome if you have!). But what the differential – and the entire drivetrain – really cares about is torque, and frankly, your “at the wheels” torque numbers from your latest dyno pull is pretty meaningless as far as that is concerned. At the same time, most people look at me like I have a third eye when I tell them how much torque our differentials are actually rated for.

Let me explain. Horsepower is really a rating of how much work can be done over a period time. In practical automotive terms, unless you’re concerned with setting a record at Bonneville, it’s a bit nebulous – it’s really just bragging rights. Conversely, torque is a measure of the engine ability to actually generate rotational force – what turns the shafts, which turn the gears, which turn the wheels. You can argue that torque and horsepower are mathematically related, and you would not be wrong. However, torque is what actually accelerates and drives the vehicle, whereas horsepower is what pulls it to its top speed. So, torque is what actually loads the drivetrain, and what can actually “shock” the differential in a severe situation. Consequently, torque capacity is a primary design criterion for developing a differential rather than horsepower.

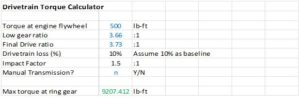

OK, so what does that mean to me, you ask? How much torque can it handle? Now you’re getting somewhere. It is important to understand that torque is multiplicative with gearing – the amount of torque delivered to the wheels during your dyno pull when in 4th gear is not the same amount that will be delivered in 1st (or any other) gear. And that’s what you have to keep in mind. The axle, and entire drivetrain, is sized so it can handle a worst-case scenario of torque loading. That, typically, occurs at vehicle launch in first gear where the torque multiplication is greatest. To get an understanding of where we need to be in terms of torque capacity, it’s necessary to do a little math. Now, this is an extremely simplified version and it doesn’t take into account several important things (such as actual tire traction available) but it makes an interesting exercise because it shows you what sort of level torque your axle really can see. If you’re used to dyno pulls that reports 500 lb-ft of torque at the wheels, this will really open your eyes.

So, you’ll need to know your gear ratios, and you’ll need to have an idea of what to use for an impact factor. This extra factor accounts for the instantaneous shock-load that the drivetrain can see when you rev up the engine and dump the clutch, or otherwise launch your car from a standing start in a very fast, abrupt, manner. Basically, the sudden application of torque winds up all of the play and back lash in the system, then smacks down real hard with the sudden change of driveline inertia, like a sort of whip effect. This kind of launch can put a shock load on the system that is substantially higher than if you simply rolled onto the throttle while moving. For a manual transmission, this impact factor can be 3:1 or more, depending on abruptness of clutch engagement. In fact, some vehicles have limited how quickly the clutch can engage just to help protect from this. For an automatic, the factor is a bit more forgiving, more in the 1.5-2:1 range, depending on the torque convertor.

TQmax = Maximum spike torque at ring gear

TQeng = Peak torque at engine flywheel

R1st = First gear ratio

Rfd = Final drive ratio

I = Impact factor

TQmax = TQeng * R1st * Rfd * I

Let’s assume a late model Mustang GT, with an MT-82 manual transmission and 3.73:1 axle gears. The numbers go as follows:

390 lb-ft * 3.657 x 3.73 * 3 = 15959.5 lb-ft.

Yes, that’s nearly sixteen thousand foot-pounds of torque. See what I mean? Now, one very large caveat to this comes in the form of traction. You will only ever develop as much torque as you have the ability to resist with tire traction – that’s really just fundamental physics. Once you’ve overwhelmed the tires, any additional potential torque goes up in smoke; it would be lost to wheel spin if you stay on the throttle. We know from experience that the S197 Mustang example in question can really only use around 9500 lb-ft in stock form before becoming traction limited, so that 16K lb-ft number we calculated is very theoretical. But someone could begin to approach that by making suspension and tire upgrades. We also didn’t account for any losses due to drag in the drivetrain system (as I said, this massively simplified). But, this does point out the order of magnitude that your axle has to put up with. A mere 500 lb-ft is nothing.

So, back to the original revised question: how much torque can it handle? That varies depending on the application. OEM applications are typically designed to a specification set by the vehicle manufacturer. However, due to the wide range of possible places that an aftermarket differential can find itself in, and equally wide range of uses, the best I can tell you is that each application is engineered to have the most torque capacity is as practical for that axle model. That’s vague, I know, but the actual answer would require a matrix table to sort out. The answer is also somewhat meaningless unless the person asking the question has a way to evaluate the traction limitations of their car, and that is a whole separate discussion…